Back in 2018 Lea Kissner and I talked about the need for a new privacy conference over dinner. Lea noted that there wasn’t a conference where privacy engineering practitioners could meet and talk about the solutions they implement in practice. Most existing privacy conferences were targeted more at privacy researchers or privacy lawyers. Lea had worked as a privacy engineer in industry for many years and I had co-founded a privacy engineering masters program and also had experience starting and running conferences. So Lea convinced me that we should work together to start a new conference. In August 2019 we met in Santa Clara, CA for the first USENIX Conference on Privacy Engineering Practice and Respect.

PEPR 2019 went well and we had planned to continue PEPR as an annual event in the Bay Area, as that seemed to be where most of the privacy engineers are. COVID derailed this plan and PEPR 2020 was held entirely online. The USENIX Association (and every other organization that runs events) struggled through the pandemic and decided they could not afford to run PEPR 2021 online as well. So, the Future of Privacy Forum and Carnegie Mellon University CyLab stepped in to co-host an online PEPR 2021 event and I presented my talk “Illustrating Priavcy Engineering Concepts with Potty Talk” from my third-floor bathroom. USENIX ran PEPR 2022 as a hybrid event (I remotely presented a talk on the design of cookie consent interfaces from my kitchen) and then returned to fully in person in 2023 and has been running PEPR in person ever since, but unfortunately I was not able to attend in 2023 or 2024.

I decided that I needed a pepper dress to wear the next time I attended PEPR in person. Most of the pepper fabric I could find was quilting cotton. I could not find any knit pepper fabric that I liked. I thought about custom printing some pepper fabric, but never found a design I really liked. A week before PEPR 2025 I decided I really needed a pepper dress and scoured the internet for suitable fabric that I could get delivered to my home quickly. Again, I mostly found quilting cotton.

I noticed that pepper PJs in knit fabrics were readily available. So I decided to order a size XXL pepper nightgown and try to cut it up and turn it into a dress. Two days later, the nightgown arrived and I got to work figuring out what to do with it. The website claimed it was 95% polyester 5% spandex knit, but the garment tag said it was 100% cotton. It feels more like polyester to me and a drop of water beads on the top. It only has about 30% stretch so I’m not sure about its spandex content. The fabric features bright red peppers on a dark grey background with black outlines.

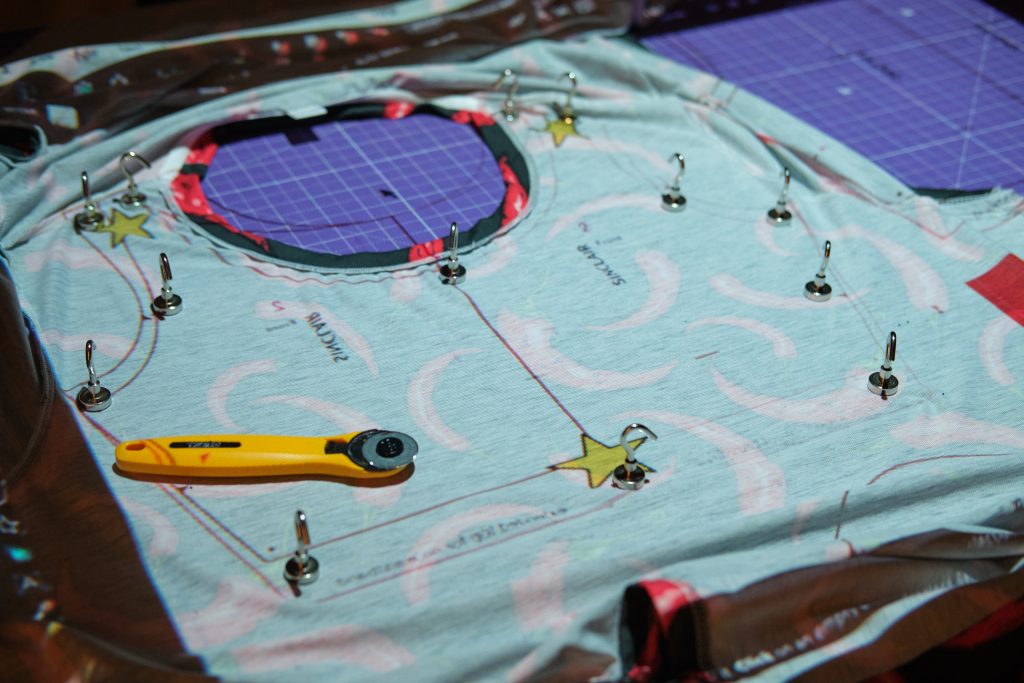

I decided to use the Sinclair (free) Valley Skater Dress pattern with a half-circle skirt from the add-on pack. I have made this pattern previously and it was pretty easy and I thought I could adapt it for this project. Because the mystery fabric did not have a lot of stretch and I know the bodice is very fitted, I decided to size up to a 6p rather than using the 4p size I had used previously. I extended the bodice by about an inch and a half as suggested when making the dress without a waistband. I cut the nightgown open at the side seams and projected the two bodice pieces onto it and cut them out, leaving the neckband and shoulder seams from the nightgown in tact.

Then I projected the sleeves onto the fabric from the nightgown sleeves and cut them out with the hem in tact so that I would not need to hem the sleeves. Finally, I had to figure out what to do about the skirt. The nightgown was not quite wide enough to cut out the pieces for the half-circle skirt. I decided to improvise and pivoted the sides of the skirt pieces in until the fit the fabric I had. I left the bottom hem in tact (and thus, not quite as rounded as the pattern called for) and I reduced the rounding on the waist and made sure it would fit the bottom of the bodice. I ended up with something closer to a one-third circle skirt than a half circle skirt.

I really wanted to add pockets to the dress but didn’t have enough nightgown fabric left for deep pockets. I decided to use scraps of cupro jersey from another recent dress project to make the pockets. This is a super lightweight and not very stretchy knit and it worked really well (although it would have been slightly better if it were dark grey to match to dress fabric) — now I want to use it for all my knit pockets. I followed the pattern for inseam pockets but extended the pocket bag a bit to make them slightly deeper. The pocket construction took as long as making the rest of the dress — reminding me of how much I hate assembling inseam pockets. The part I really struggle with is stitching the top and bottom of the pocket openings without catching any of the pocket bag on the outside of the pocket. After trying and failing on the first pocket I unpicked it and used my trusty glue stick to line up the pockets and then sewed them with my edge foot. It still took way too long!

After I assembled the pockets it was easy to attach the skirt to the waistband. Since everything was already hemmed, I added a label and I was done… until I looked at the back and noticed a lot of bunching at the waist.

I decided to add a simple swayback adjustment, and then I was really done.

And then it was time to accessorize! I ordered a bag of plastic pepper charms and added jump rings to turn them into pendants.

This morning we presented our UsersFirst framework at the PEPR conference. As you can see I was fully on theme with pepper dress, necklace and socks. And the pockets came in handy for the microphone pack.